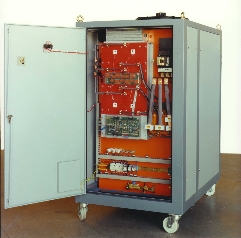

Main Unit

|

PULSE RECTIFIERS FOR ANODIZING |

|

|

ADVANTAGES IN USING PULSE RECTIFIES IN ANODIZING |

|

|

Choice of current value (Ampere)The pulse rectifiers are characterized by 3 values:

|

|

Example:

|

Therfore:

|

|

Max voltage The pulse rectifiers are provided for a 22V max voltage (instead of 20V max as for conventional rectifiers) to have the possibility of pulse superposing. |

TECHNICAL FEATURES |

|

Control: By means of SCR set on: primary or secondary side

Rectifier circuit: Main transformer: according to IEC 742 standard "Safety isolating transformers"

General switch:

Cooling:

Protections:

Voltage/current control:

|

STANDARD MODELS (22V) |

| In | Imax | Ieff | Dimensions (mm.) |

| 1000 A | 1500 A | 1350 A | 1000x1000x2000 (h) |

| 2000 A | 3000 A | 2700 A | " |

| 3000 A | 4500 A | 4050 A | 1000x1500x2000 (h) |

| 4000 A | 6000 A | 5400 A | " |

| 5000 A | 7500 A | 6750 A | 1100x1700x2000 (h) |

| 6000 A | 9000 A | 8100 A | " |

| 8000 A | 12000 A | 10800 A | " |

| 10000 A | 15000 A | 13500 A | " |

| 12000 A | 18000 A | 16200 A | 1200x2200x2200 (h) |

| 15000 A | 22500 A | 20250 A | 1200x2800x2000 (h) |

| 20000 A | 30000 A | 27000 A | " |

| 25000 A | 37500 A | 33750 A | 1400x3800x2200 (h) |

|

|

|